Choose one

or multiple languages

0,1,1

- German

- English

- Chinese

- Spanish

Shore hardness test

The Shore hardness test is mainly used to determine the hardness of Elastomers and plastics. It is not normally used for Metals and ceramics.

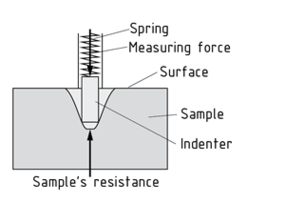

In the Shore hardness test, a spring-loaded hardened Steel pin penetrates into the test piece. The depth of penetration into the Material to be tested indicates the Shore hardness, which is measured on a Scale of 0 Shore (2.5 millimetre penetration depth) to 100 Shore (0 millimetre penetration depth).

Since this measuring method is highly temperature-dependent, it is important to maintain a test temperature of 23°C.

A distinction is made between the following methods:

- Shore A for soft elastomers (the indenter is a needle with a blunt tip)

- Shore D for tough elastomers (needle with a spherical tip)

- Shore B and Shore C combine the Shore A needle tip with the Shore D test Force and vice versa

A similar method is used to determine the micro-hardness of elastomers (international rubber hardness degree).