Seleccione uno

o más idiomas

0,1,3

- Alemán

- Inglés

- Chino

- Español

Thermomechanical testing

Thermomechanical tests are performed to determine the characteristic values of a Material or component under dynamic thermal and mechanical loads. Thermomechanical loads are particularly relevant when designing and Dimensioning components subject to stresses such as stationary gas turbines and aircraft engines.

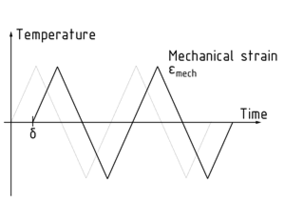

During the tests, a deformation Sensor applying an oscillating Force at a defined frequency subjects the sample to a mechanical Bending, stretching or shear load. The variable temperature profile during the test is also defined.

The material deformation is measured in terms of amplitude and phase displacement. Various load types are possible, including

- in-phase test with elongation,

- out-of-phase test with pressure or

- phase-displaced test (clockwise diamond test, counter-clockwise diamond test).

The measurements recorded depict the sample's viscoelastic properties according to load in a time-temperature function. The out-of-phase test normally generates the highest stresses. The test indicates the number of cycles to failure.

Low cycle fatigue testing with thermal startup and shutdown procedures is also possible. Cyclic Relaxation with subsequent Creep fatigue can occur in the material's creep range.